Why do our clients use Liberty for specialty fabrication?

Why do our clients use Liberty for specialty fabrication?

SPEED. COST. QUALITY.

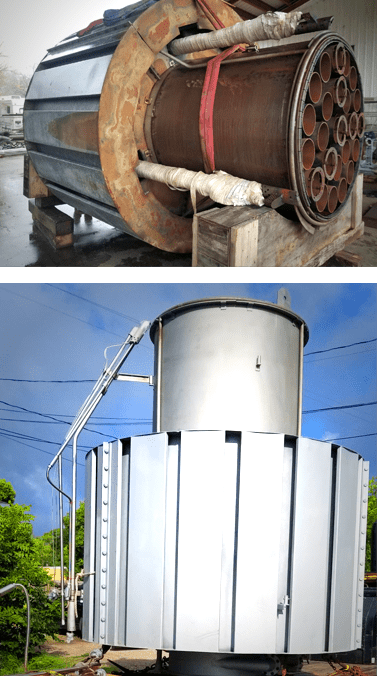

Liberty Flare’s fabrication division is capable of designing, fabricating, repairing, or rebuilding OEM or replacement parts and components commonly found in flare stacks. We stock many standard replacement parts or can directly source specialty components. We maintain inventory of rolled alloys and various types and diameters, enabling us to rebuild components in a short period of time for our clients.

All components designed and fabricated in our shop are of high-grade domestic steel and can be hot dip galvanized to maximize system lifetime.

We at Liberty Flare feel that keeping all aspects of the project in-house is crucial to guaranteeing quality assurance and cost effectiveness which is passed on to the customer.

Liberty Flare self performs many aspects of the fabrication process, ensuring that we can tightly control quality and cost of your project. Our shop management has over 35 years of experience and our senior technicians are trained and experienced in structural design and loading.

At Liberty, we strive to produce the best components available to our valued customers at a competitive price, with decades of field experience influencing the best-in-class design and engineering.

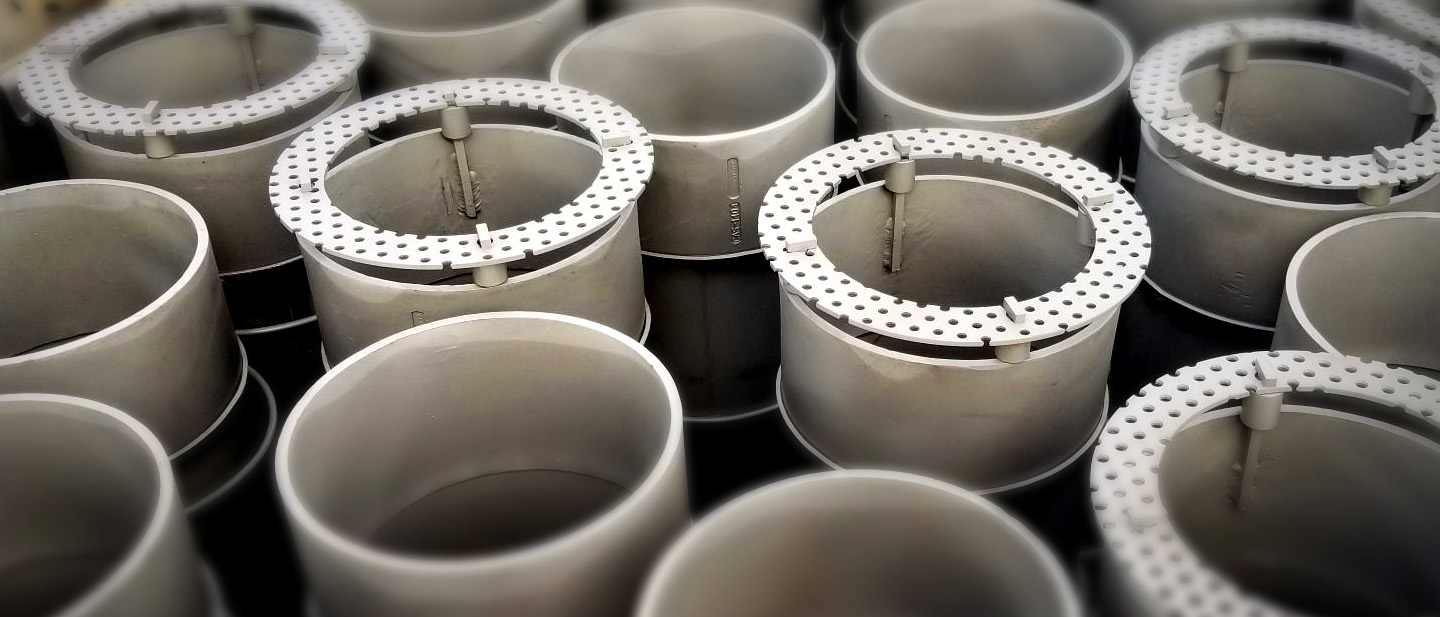

Custom Fabrications – Given the complexity of working at heights, many components of flare and vent stacks need to be modified or re-designed to allow for proper installation and durability. In order to maximize useful life in corrosive and high heat environments, we utilize specialty alloys ranging from stainless steel to Inconel and Hastelloy. Our customers have asked us to fabricate:

- Flares

- Structures and supports

- Piping and manifolds

- Tubing

- Lifting systems

- Skirts and floors

Flag Poles – Liberty Flare can design and engineer custom flag poles from thirty feet to two hundred feet in height. Before any manufactured product leaves our shop, our comprehensive quality control process will ensure your long-term satisfaction.

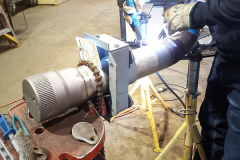

Whether damaged by weather or process conditions, your Flare Tip is an essential component of your flare system that requires a critical path focus and repair schedule. Liberty Flare can repair or refurbish your damaged repair tip in situ or in our state-of-the-art fabrication facility. Liberty is experienced and skilled at working with high-alloy metals, and certified in weld repairs for these valuable components.

Flare tips repairs include:

- Inspection of all components (including NDT)

- Weld repair

- Metal replacement/fill

- Structural repair

- Flange and bolt machining/repair

- Part replacement

- Blasting and painting

- Galvanizing

Liberty Flare has extensive experience repairing and refurbishing burners and replacing or repairing components, whether in situ or in our fabrication shop.

Burner efficiency requires an efficient and routine maintenance process. Process upsets, wear, and corrosion from water and salt air create fouling and damage to burner tips and risers. The Liberty technicians can clean – repair – replace components in the field or bring the equipment to our facility to turnkey a full burner refurbishment. Radiant wall burners are ideally repaired in shop, for example, as access in situ is often restricted, and welded tip repairs can be completed in ideal environmental conditions.

Field services on burner assemblies include:

- Inspection

- Louver lubrication

- Tip blasting/cleaning/replacement (threaded and welded tips)

- Re-set tip orientation and configuration to specifications

- Riser replacement

- Weld repairs (including stainless, high carbon and high alloy metals)

- Viewport maintenance and replacement

If you need to complete a full refurbishment of your burner or component, Liberty Flare can manage your turnkey project. Ask us about past projects, customer references, and how we can manage your burner repairs in tandem with your flare system repairs!

Given the complexity of working at heights, many components of flare and vent stacks need to be modified or re-designed to allow for proper installation and durability. In order to maximize useful life in corrosive and high heat environments, we utilize specialty alloys ranging from stainless steel to Inconel and Hastelloy.

Our customers have asked us to fabricate:

- Flares

- Structures and supports

- Piping and manifolds

- Tubing

- Lifting systems

- Skirts and floors

Liberty Flare, LLC is a specialty contractor providing maintenance, repair, inspection, installation and design services on industrial flares and vent stacks. With over five decades of experience in working at heights, our highly trained team of technicians are dedicated to safety, quality, integrity, and customer satisfaction.